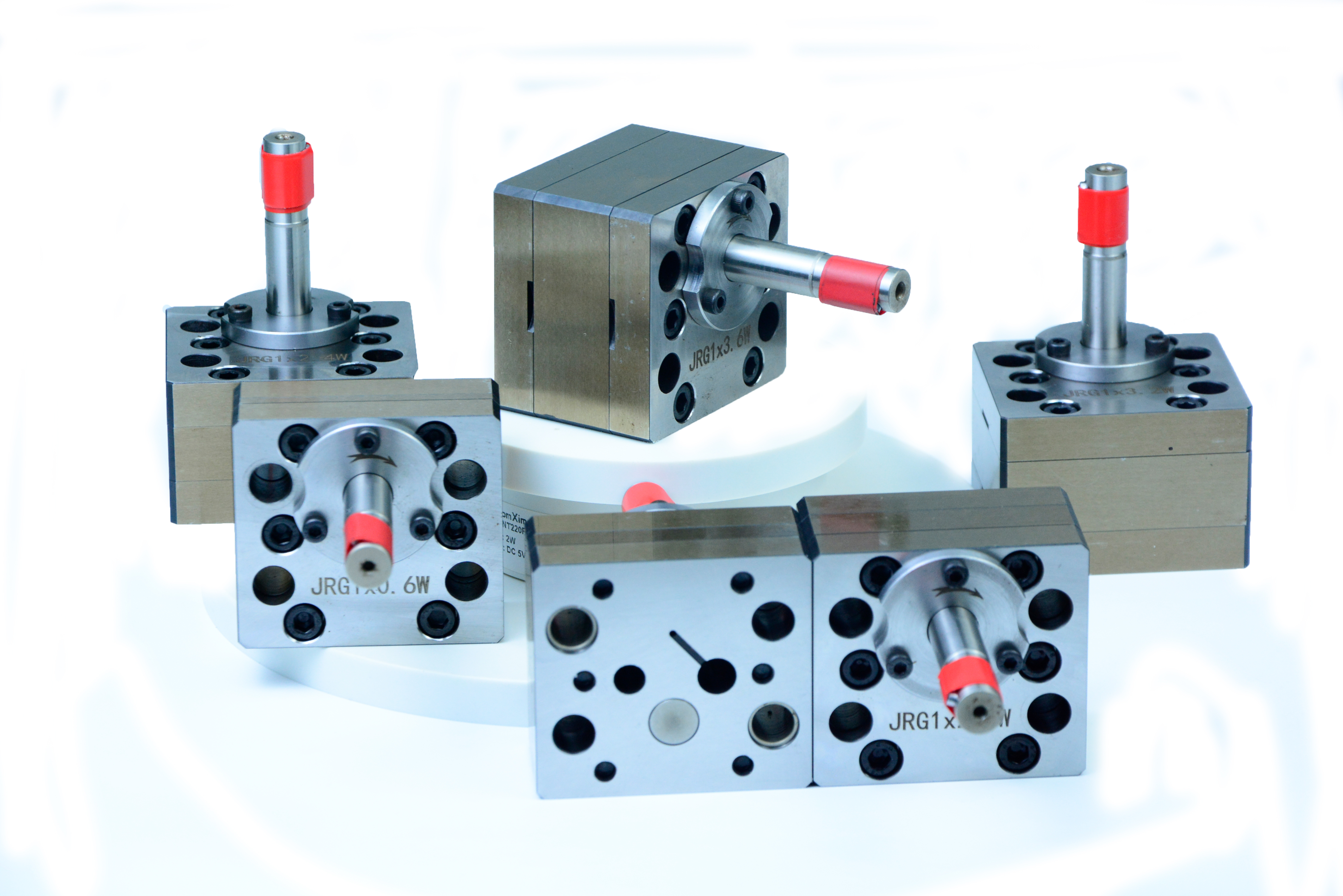

In modern industrial systems, precise fluid transportation and control are key to ensuring product quality, improving production efficiency, and achieving process automation. Gear metering pump, as a high-precision positive displacement pump, plays an indispensable role in multiple specific fields due to its stable and reliable performance. It is mainly applied in the following situations:

1. Chemical and pharmaceutical processes that require extremely high measurement accuracy

In the process of fine chemical and pharmaceutical production, the amount of raw materials added often needs to be precise to the milliliter or even microliter level. Any small deviation can lead to chemical reaction failure or substandard drug ingredients. The gear metering pump rotates in the pump chamber through two tightly meshed gears, forming a closed space to transport fluid. The volume of liquid discharged per revolution is fixed, thus achieving extremely stable and accurate flow output. Whether adding expensive catalysts dropwise to the reaction vessel or injecting specific proportions of components during the synthesis process, it can ensure the accuracy of the ratio and guarantee product quality from the source.

2. Handling high viscosity or sensitive liquid media

Many industrial fluids, such as polymer melts, resins, paints, inks, chocolate pastes, etc., have high viscosity characteristics. Ordinary centrifugal pumps have low efficiency or even cannot work when dealing with such media. Gear metering pumps rely on the strong meshing and propulsion of gears to effectively overcome fluid resistance and achieve stable delivery. At the same time, its smooth shear force transmission method causes minimal damage to polymer chain structures or fluids containing sensitive fillers (such as certain coatings), and can effectively maintain the original characteristics of the material, which is crucial for subsequent product molding and performance.

3. Quantitative addition and coating on automated production lines

In automated production lines such as automobile manufacturing, electronic products, building materials, etc., it is often necessary to quantitatively inject or evenly apply lubricants, sealants, adhesives, etc. Gear metering pumps can be precisely matched with PLC (Programmable Logic Controller) and servo motors to achieve timed and quantitative automated fluid supply. For example, in the installation of car windshields, it is used to apply sealant; In food packaging, it is used for precise injection of fillings. This precise control not only ensures process consistency, but also effectively avoids material waste.

4. As the core component of precision detection and analysis instruments

Gear metering pumps also play an important role in laboratories and various analytical instruments. For example, in environmental monitoring equipment, it is used to accurately extract water samples or chemical reagents; In medical analytical instruments, it is used to transport blood samples and detection reagents. In these scenarios, a small amount of liquid is required, but the requirements for repeatability and accuracy are extremely high. The high-precision characteristics of gear metering pumps perfectly meet this core requirement.

In summary, when the production or experimental process has strict precision requirements for fluid transport volume and ratio, or requires the handling of media with special properties and the pursuit of high automation and stability, gear metering pumps become the preferred solution. It is not only a tool for achieving precision measurement, but also an indispensable technological cornerstone in the process of modern industry moving towards intelligence and refinement.